Best Quality Color Steel Coils Sheets Roofing Corrugated Tile Roll Forming Making Machine

Basic Info.

| Model NO. | tile forming machine |

| Transmission Method | Electric |

| Coil Width | 1220mm |

| Control System | Mitsubishi PLC and Transducer (Japan) |

| Suitable Raw Materials | Color Steel Coils |

| Yield Strength of Raw Material | 235MPa or 34ksi |

| Suitable Coil Thickness | 0.5 mm - 0.6 mm |

| Voltage | 440V/60Hz, 3 Phase |

| Roller Grinder Milling | Cr12 MOV with Quenched Treatment |

| Diameter of Shaft for Rollers | 72mm |

| Main Power | 5.5kw |

| Transport Package | 40gp |

| Specification | CE SGS BV |

| Trademark | Zhongyuan |

| Origin | Hangzhou |

| HS Code | 84552210 |

| Production Capacity | 10sets/Month |

Product Description

Best quality color steel coils sheets roofing corrugated tile roll forming making machineOur Advantages

Product Parameters

About Tile Roll Forming Machine

| Item | Specification | |

| Material | Type | Color steel coils |

| Thickness(mm) | 0.5 mm - 0.6 mm | |

| Yield strength(mpa) | 235Mpa or 34Ksi | |

| Roller material | High grade No.45 forged steel, with digital-controlled procession,plated wit chrome on surface | |

| Production speed(m/min) | About 5-6m/min. (including the cutting& pressing time) | |

| Step distance | Adjustable according to requirement (>=250mm) | |

| Speed adjusting mode | AC Frequency | |

| Roller drive | Decelerating motor + Chain drive | |

| Cutting mode | Hydraulic cutting | |

| Cutter material | Cr12 MOV with quenched treatment | |

| Length measurement | Encoder | |

| Control mode | Mitsubishi PLC and transducer (Japan) | |

| Operating mode | Button + Mitsubishi Touch screen | |

| Main motor power(kw) | 5.5KW | |

| Hydraulic station power | 7.5K W | |

| Total power(kw) | 13KW | |

| Uncoiler's loading capacity | Max. Capacity: 5000kgs | |

| Machine`s size | 8.45m*2.1m*1.73m | |

| Machine weight | 11100KG | |

Components of machine: | ||

| Manual decoiler | 1 pc (capacity:5 tons) | |

| Guiding Equipment | 1set | |

| Covering film device | 1set | |

| Roll Forming Equipment | 1 set (gear box transmission) | |

| Pressing equipment | 1set | |

| Post-cutting Equipment | 1set | |

| Hydraulic Station | 1set | |

Process flow:Decoiling the sheet→Guiding sheet →Roll forming→Pressing sheet→Measure length and cutting the sheet→Product to the run out table | ||

Packaging & Shipping

1.1*40GP container for loading one set machine with decoiler.2. Main machine body and decoiler is load naked (tighten to container with steel wire rope).3. Spare parts and operating tools are loading in tooling box.Company Profile

Established in 2003, Zhongyuan Machinery Factory is experienced manufacturer of metal forming machinery with ISO quality system.

Our R&D department is staffed with senior engineers who has more than 20 years experience in metal forming machine industry, So we are able to assist customers with professional designing and solution.

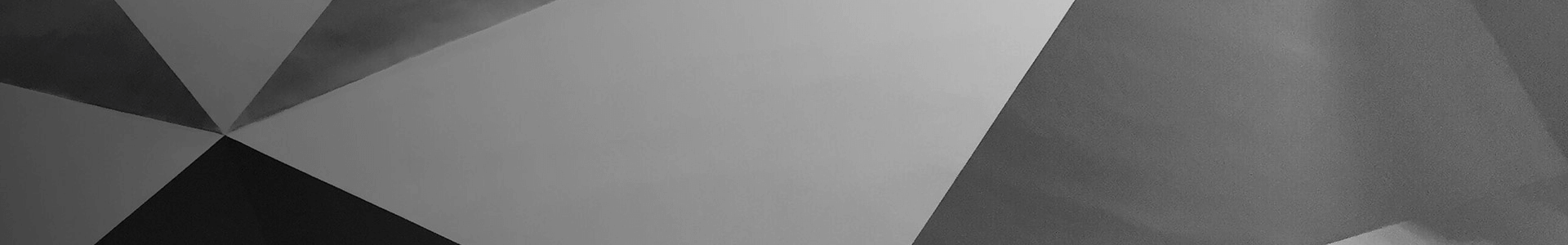

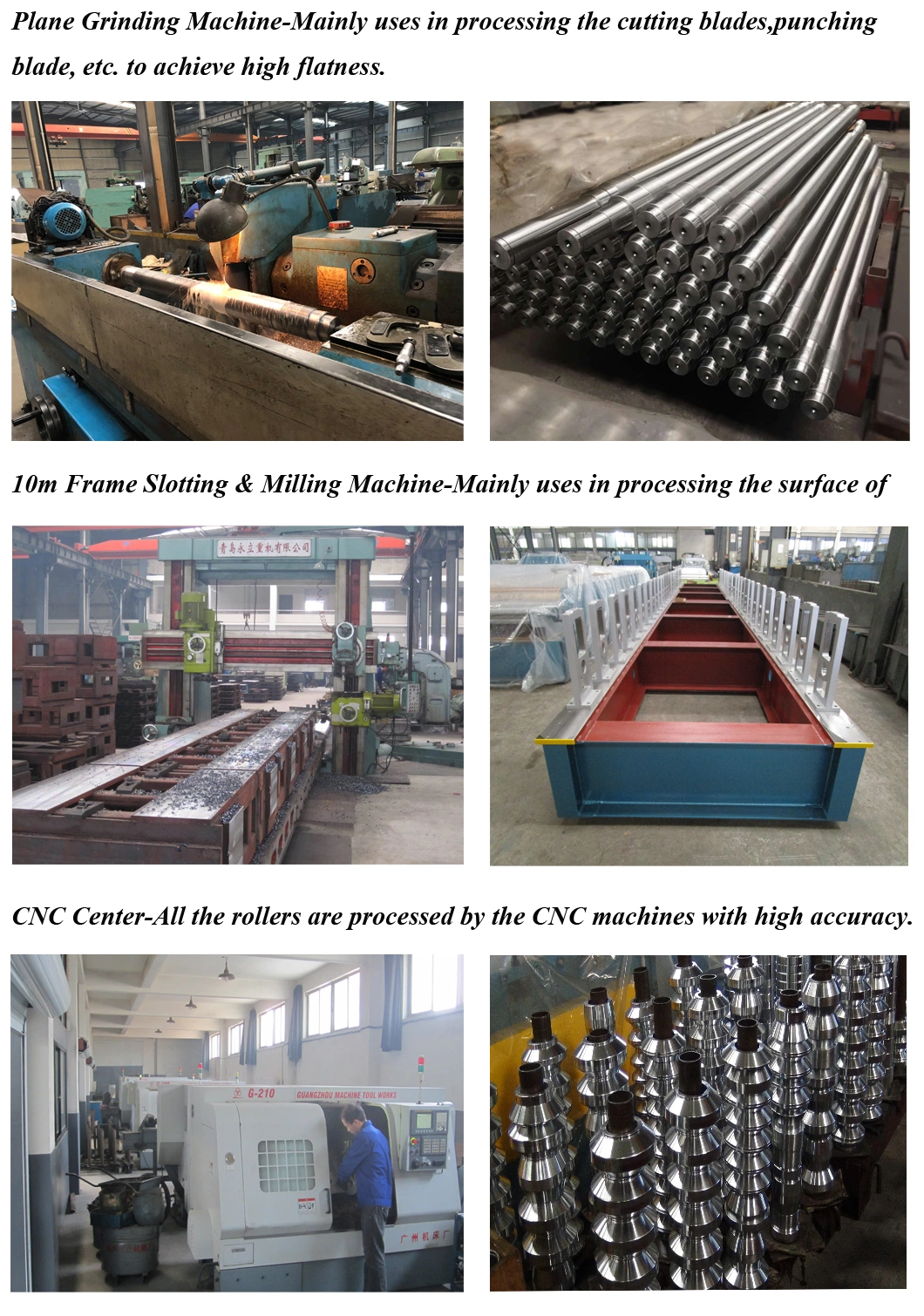

We are"All-in-house source" - from raw material to the final high-precision forming machine. Our own tooling center is equipped with CNC turning-lathes, Grinding machine for roller shaft, Heavy planing machine,etc,which allow us to complete the majority of our processing procedures on-site. So we can better control the machine quality and delivery time of machines.

Our range of products: sandwich panel production line, roof tile forming machine, cladding forming machine, metal decking forming machines,etc. We also can supply steel coils,EPS sandwich panels,PU sandwich panels to suit diverse requirements of our global customers.

Today, we have exported our machines to America, Chile, Mexico, Bolivia, Brazil, Colombia, Argentina, Ecuador, Honduras, Australia, Fiji, Papua New Guinea, Kuwait, Syria, Oman, Saudi Arabia, U.A.E, Nigeria, Tanzania,Ethiopia, Gana, Guinea,South Sudan, Algeria, Niger, Philippines,Indonesia,India, Russia, Azerbaijan and Kazakhstan.

We have rich experience for metal forming machine solution,competitive price and excellent service. We will continue to do our best to supply perfect products and service for customers. Invite you to contact us for further information.

FAQ

1) Q: Are you manufacturer or trading company?

A: We are manufacturer and trading company .2) Q: Do you provide installing and training overseas?

A: Overseas machine install and worker training services are optional.3) Q: How is your after sales support? A: We provide technical support on line as well as overseas services by skillful technicians.4) Q: How does your factory do regarding quality control? A: There is no tolerance regarding quality control. Quality control complies with ISO9001. Every machine has to past testing running before it's packed for shipment.5) How can I trust you that machines pasted testing running before shipping?

A: 1) We record the testing video for your reference. Or,2) We welcome your visit us and test machine by yourself in our factory.6) Q: Do you sell only standard machines?

A: No. Most machines are made to order.7) Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. We are Gold supplier of Made-in-China with SGS assessment (Audit report can be provided).